Special Protective Conduits

Explore Our Specialty Conduit Products

IBIS Electro-Products provides a wide range of specialty conduit products. Through our personal experiences in industry and through working with world-renowned product manufacturers, we have carefully curated a collection of specialty conduits that will be sure to target any application you desire.

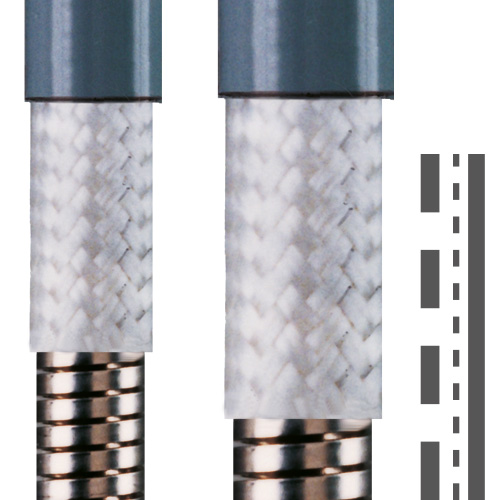

Our special protection conduits for medical and sensor technology with very small dimensions made of metal and plastic can be sheathed with different materials and fitted with suitable fittings depending on the application. Other special products include braided hoses, bundling spirals and fire protection hoses.

IBIS Electro-Products Offers Specialty Conduits Worldwide

IBIS Electro-Products sells specialty conduits, flexible tubing that is made for very specialized applications. They have certain properties that are manufactured into them to ensure they conform with their intended use.

Specialty conduit properties are often driven by factors involving application environment, mechanical endurance, or installation space. Characteristics to consider could be: high or low temperatures, sunlight, humidity, mechanical vibration, flexibility, heat, flammability, weld splatter, tight mounting location.

Popular specialty conduit materials used are: stainless steel, calcium silicate, silicone, fiberglass, polyamide, Teflon (PTFE)

We supply only the Flexa brand of conduits. The Flexa family of flexible specialty conduits include the names:

- OPTOflex, Very flexible, silicone jacketed conduit, for fiber optics protection

- SPR & SPR-VA, small diameter conduits, no-stretch, liquid and non liquidtight

- SPR-VA small diameter welding laser fiberoptic bundle protection, PU, liquidtight

- FLEXAhightemp, fire protection conduit, silicone sheath, calcium-silicate braid, 350°C

Specialty conduits are used in the protection of wires or fiber optic bundles in applications needing very specific solutions that they were intended for. If the specialty conduit is manufactured for the fiberoptic industry, then they would be used in fiberoptic applications. For example, a specialty conduit to be used for fiberoptic bundle protection could require a conduit to have the following characteristics: liquidtight, strong protective wall, highly flexible, non-stretch and capable of withstanding high temperatures.

If the specialty conduit is designed for use with laser welders, then they will be used with laser welding machinery applications and capable of tolerating weld splatter and repetitive motion. As a rule, they provide a solution for a very specific application. Due to their highly specialized nature, there are no real general applications for them.

Specialty conduits should be used when you have an application that needs a high specialized conduit for wire, cable or pneumatic hose protection and management. They are the most suitable for their intended application and will be able to handle the job most adequately.

Specialty conduits shouldn’t be used in their non-intended applications. While in an emergency, they may be used in most applications, their usage would be “over the top”, unnecessary and temporary. If the requirements of the application are not unusual or extreme, then a more common non-metallic or metallic conduit variety would be a better choice.